Industry 4.0 and networking

Simple retrofit networks

Success-Stories

Globalisation forces vehicle manufacturers to continuously shorten their production times, reduce manufacturing costs and optimise their processes. This means that the suppliers also have to rethink their logistics processes. The global technology company Continental employs the “just-in-sequence” principle in Regensburg to ensure that the necessary materials are delivered to the production line in perfect sequence.

Automotive suppliers work under high pressure to develop ever more efficient manufacturing methods and shorter product cycles. With less operating space, less infrastructure and shorter development times as well as highly automated processes it is crucially important to provide high-quality products on schedule.

Lean structures and lean processes are a challenge for every company. In order to optimise the efficiency of the value adding processes and to improve the company’s competitive standing, Höft & Wessel use a simple machine data recording system from WERMA Signaltechnik.

StockSAVER offers a robust error-free system as it is no longer necessary to scan withdraw-als of stock neither is there a danger of duplicate bookings being made nor are arithmetically calculated stock level errors possible.

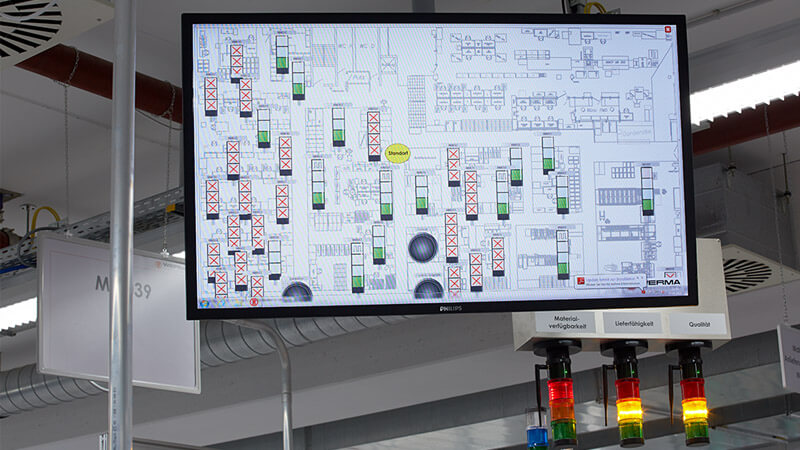

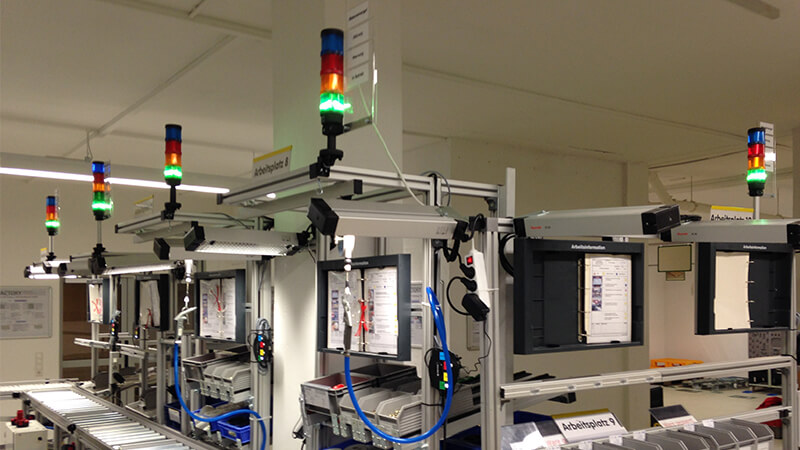

The machines are located in several workshops and different buildings. The signal towers show the status of the machines locally but do not allow any centralized overview. The Production Manager wanted to gain transparency of the complete production operation by seeing the status of all machines in one view.

StockSAVER is a maintenance-free system which is easy to retrofit to any FIFO flow rack.Sensors fitted to the flow racks ejhnsure complete transparency of stock levels and safeguard against material running out or misplaced stock.The system works very simply:sensors monitor the number if bins held on the FIFO flow racks.

Since VETEC has long relied on signal towers from WERMA, which quickly and clearly indicate faults on each machine and thus provide visual monitoring, just the wireless slave transmitter had to be fitted onto the existing tower. Thanks to the WERMA system, it was possible for the first time to record, clearly distinguish and visualise productive and non-productive times.

The Yamauchi technology company in Hasselt, Belgium, has set itself the goal of continually optimising its own production process and eliminating downtimes by focusing on Industry 4.0 concepts. Looking for a solution the company came across the intelligent, wireless retrofittable SmartMONITOR system from WERMA. The system provides information in real time about the frequency and causes of downtime, thereby providing the basis for further investigation of the root causes of downtime and possible optimisation solutions.

With over 80 employees, Flestic supplies to a wide range of industries, such as food, cosmetics, automotive, household and care. The Dutch plastic packaging specialist relies on SmartMONITOR from WERMA and optimizes its production within a few weeks. At FLESTIC, more than 40 machines are equipped with SmartMONITOR.