Our products and solutions make processes safe and keep them running efficiently

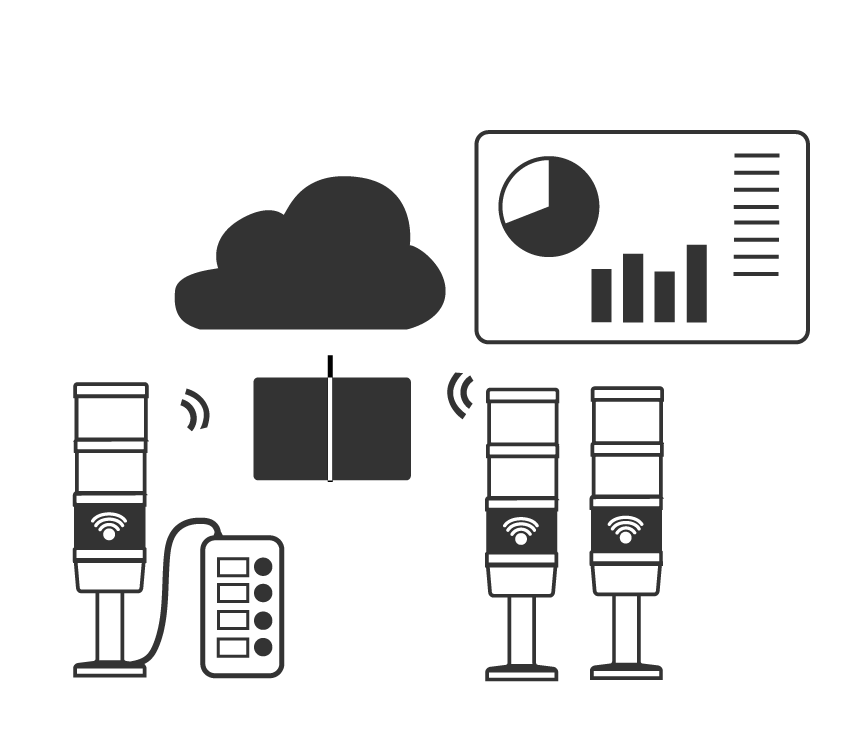

With the radio-based, innovative systems for process optimisation for industry, production and shipping logistics, machines or workstations are networked with each other by radio, a unique feature worldwide. They thus represent a simple, retrofittable and ready-made solution for reducing downtimes or for automatic replenishment control. See for yourself "live", because we don't just supply systems that can simply be retrofitted and used immediately. Our solutions are ready-made solutions, can be used immediately and function "out-of-the-box". Because at WERMA signal technology is thought through further!

Learn more about interesting aspects and experiences of our new and further developments and experience our systems live!