News about WERMA

Success Story: “This MDC system is simply unbeatable!”

Automotive supplier Eberle Rieden is optimising its production with SmartMONITOR from WERMA

The Eberle Rieden company is based near Neuschwanstein Castle, in the heart of Bavaria, on the idyllic Forggensee lake. Founded 33 years ago as a tool manufacturer, the company now produces stamped and stamped-bent parts for a large international customer base covering a wide range of industries, primarily in the automotive sector and other sectors such as the electrical and furniture industries. Eberle Rieden is proud of its employees at the site, who now number almost 180, and of its current annual turnover of 34 million euros. For more than 14 years, the company has been part of the KERN-LIEBERS Group, made up of more than 50 different companies, and is therefore extremely well connected worldwide.

Eberle Rieden – the specialist for stamping and bending technology

Frank Laurin has been working for Eberle Rieden for more than three years. As Production Manager he is responsible for the manufacture of all the products produced in the 10,000 m² facility and for the employees who work there in three shifts. “I think everyone has come into contact with one of our products at some time or another”, says Frank Laurin. “Unfortunately, however, our little gems can’t always be seen at first glance. You can find them as a locking bar or airbag clip in your car, for example, or as a hinge on one of your pieces of furniture.”

Gerhard Schöll, Managing Director at Eberle Rieden says:“In addition to maintaining our reputation as ‘the problem solver in the market’, we have adopted a zero defect policy for all our products, processes and services. This made it very important for us to find a smart, transparent and clever system for our production area that would make maximum transparency possible.”

Looking for a solution

When asked about the exact nature of Eberle Rieden’s problem, Frank Laurin explained: “We have a top-of-the-range production facility with great, motivated employees – yet we always had two problems to contend with: firstly, the available data was not up-to-date and not detailed enough, and secondly, employees had to handwrite important information and manage the records in paper form. This manual procedure was very prone to errors, as information was lost or not passed on to the next shift or was misinterpreted.” Managing director Gerhard Schöll agrees with his colleague: “The amount of detail recorded was insufficient to provide reliable data or allow us to derive key figures. A professional solution was urgently needed!”

He adds: “Since our customers are primarily from the automotive industry, the requirements in terms of speed and quality are extremely high. We needed a system that would meet the most stringent demands yet still be quick and easy to operate.”

Inspired right from the start

“I had read an article on the internet about the new MDC system from WERMA”, Frank Laurin explains. “The idea that we could use our existing signal towers appealed to me from the very beginning.” Then everything happened really quickly: “I contacted WERMA and just two days later a package arrived here containing everything we needed.”

We started out with seven machines in a specific production area that could be separately observed. This pilot project was so successful that just five months later the next production area was added. “SmartMONITOR immediately met all our expectations”, says Frank Laurin. “I was enthusiastic from the very first minute and still am”, he adds.

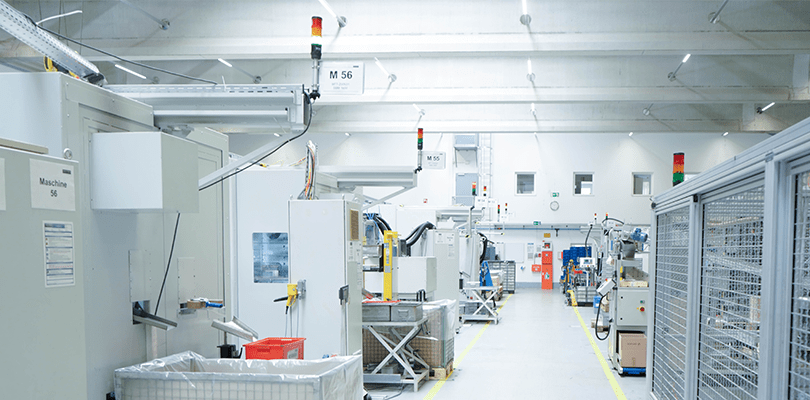

In the meantime, a WERMA signal tower has been installed on almost every machine in the production plant. Older machines have been retrofitted and all new machines are ordered complete with WERMA beacons, including SmartMONITOR. Frank Laurin is delighted: “At the moment we have 60 machines at Eberle Rieden that are equipped with SmartMONITOR. This equates to more than 95% of the entire plant.” He is convinced that maximum transparency and continuous optimisation of the production processes are only possible “if as many machines as possible are integrated into the system”.

SmartMONITOR from WERMA works like this

Eberle Rieden has been using “SmartMONITOR”, WERMA Signaltechnik’s simple and ingenious radio-based MDC alternative (machine monitoring and data collection), for more than three years now. Intelligent networking of the signal towers creates a simple, low-cost and retrofittable alternative to conventional, complex MDA systems. With SmartMONITOR, faults and non-productive time can be quickly identified, analysed and documented. This shortens reaction times, prevents downtime and increases productivity.

The SmartMONITOR system comprises radio transmitters, a radio receiver and the software. The robust and proven wireless network (868 MHz) for production environments intelligently searches for the best connection by itself, and thereby ensures the simplest integration into your production process. The radio transmitter is simply integrated as an additional element in the existing WERMA signal tower via Plug & Play and monitors the status or piece counts of machines, equipment and manual workstations. This data is transmitted to the radio receiver via radio, where it is seamlessly transmitted and saved in a Microsoft SQL database. The type, age and make of the machine are irrelevant, since the WERMA MDC system requires only a WERMA signal tower as an interface.

Everything at a glance, with just one click

Frank Laurin underlines how easy it was to set up the system: “We installed the software, connected the radio receiver to the computer and configured the system step by step. The software guides you reliably every step of the way. We then integrated the radio transmitters into the signal towers and our MDC system was ready for operation. Incredible, don’t you think?” He adds: “It only takes four hours to integrate a new machine into our SmartMONITOR system – that really is unbeatably fast!”

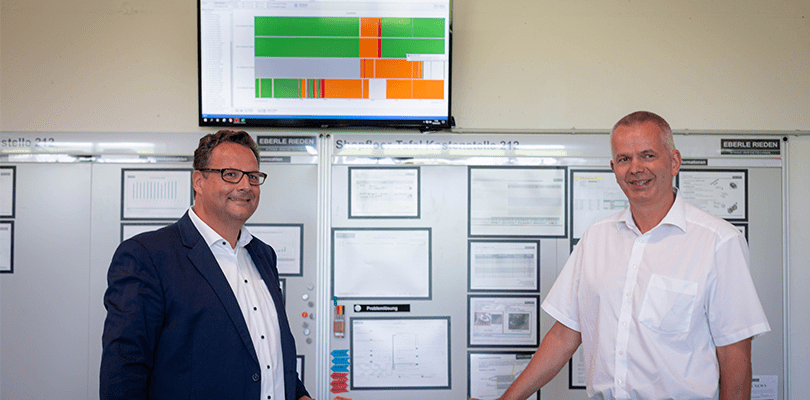

Not only the production manager, but also the planning and tool manufacturing departments and the supervisory staff in the production department work with SmartMONITOR and the software on a daily basis. “When the supervisors of the various production areas come into the office in the morning, the first thing they look at is invariably the control console display. Here everyone can see at a glance what has happened during the last 24 hours, which machine is working at what capacity and whether there are any problems. If there are any faults, you can look at these in detail, straight away, and intervene directly”, says Frank Laurin. “If the control console display shows mostly green bars, I have a much more relaxed start to the day, of course.”

Continuous improvements thanks to SmartMONITOR

“The data and values that the WERMA software provides form the basis for our daily 15-minute shop floor meetings and for our continuous improvement process,” says Gerhard Schöll. At Eberle Rieden, existing faults and the associated additional information provided by employees are examined and used as the basis for targeted measures and long-term optimisations. These may include specific training for employees, for example, the reassessment of entire processes, or tool adjustments.

The data from the system is also increasingly used when it comes to customer complaints: “If a complaint is received, the software can be used to clearly determine whether there was a malfunction at the time of production, for example, or whether there are other issues that could have resulted in quality problems”, explains Frank Laurin.

From Bavaria to the whole world

“We have become real fans and are so enthusiastic about the WERMA system that we would like to establish it throughout the entire KERN-LIEBERS Group”, says Managing Director Gerhard Schöll. “Mr Klingenberg from the Schramberg facility is particularly active in this respect. He is showing our colleagues around the world how quickly and easily SmartMONITOR can be introduced at any time and what great potential can be unlocked.”

Kai Robert Klingenberg, who has been working as head of the KERN-LIEBERS Production System (KLPS) since January 2015, says: “In demanding manufacturing processes and complex production facilities, it is not always easy to identify problems and wastage, and especially their causes. This is where a clever MDC system can be an effective aid and this is why I supported my colleagues at Eberle-Rieden in introducing the WERMA system.” He adds: “SmartMONITOR not only helps us to provide and process status data and key figures, but also gives employees a user-friendly tool that allows them to recognise deviations in the process, identify possible causes and document any remedial measures.”

Managing Director Gerhard Schöll adds: “The entire system, and the software in particular, are extremely clear and very easy to use. Employees are not overwhelmed by confusing, complex software. With SmartMONITOR they can evaluate precisely the data they need.” He concludes: “It is not just the cost-benefit ratio that is unbeatable. I think that when a system is applied and used by the managing director as well as by each machine operator, this speaks for itself.”